Facility

Tydex production facilities occupy 1500 square meters and consists of the following departments: optical components manufacturing, optical coating, device manufacturing and R&D.

R&D activities are focused in two key area: optical components manufacturing and research, developing and manufacturing of terahertz instruments, devices and components.

Optical manufacturing is the primary department, subdivided into several sections.

Metalworking section consists of two areas. The first is responsible for manufacturing special purpose tooling for production of optical components (fig. 1, 2). The second one produces various parts and assemblies for instrument manufacturing, using a variety of metals (titanium, stainless and tool steel, brass, duralumin, non-metallic materials). The equipment stock includes lathes and milling machines made by JET, Russian-made IZh250 and 16K20, providing the capabilities of metal cutting (up to 200 mm), turning (up to 350 mm), spherical turning (up to 250 mm), milling (up to 250 mm) and drilling. This section meets the following precision requirements: tolerance on linear dimensions ±10 μm, tolerance on angular dimensions ±20', surface roughness Ra 0.8.

Fig.1

Fig.1

Fig.2

Fig.2

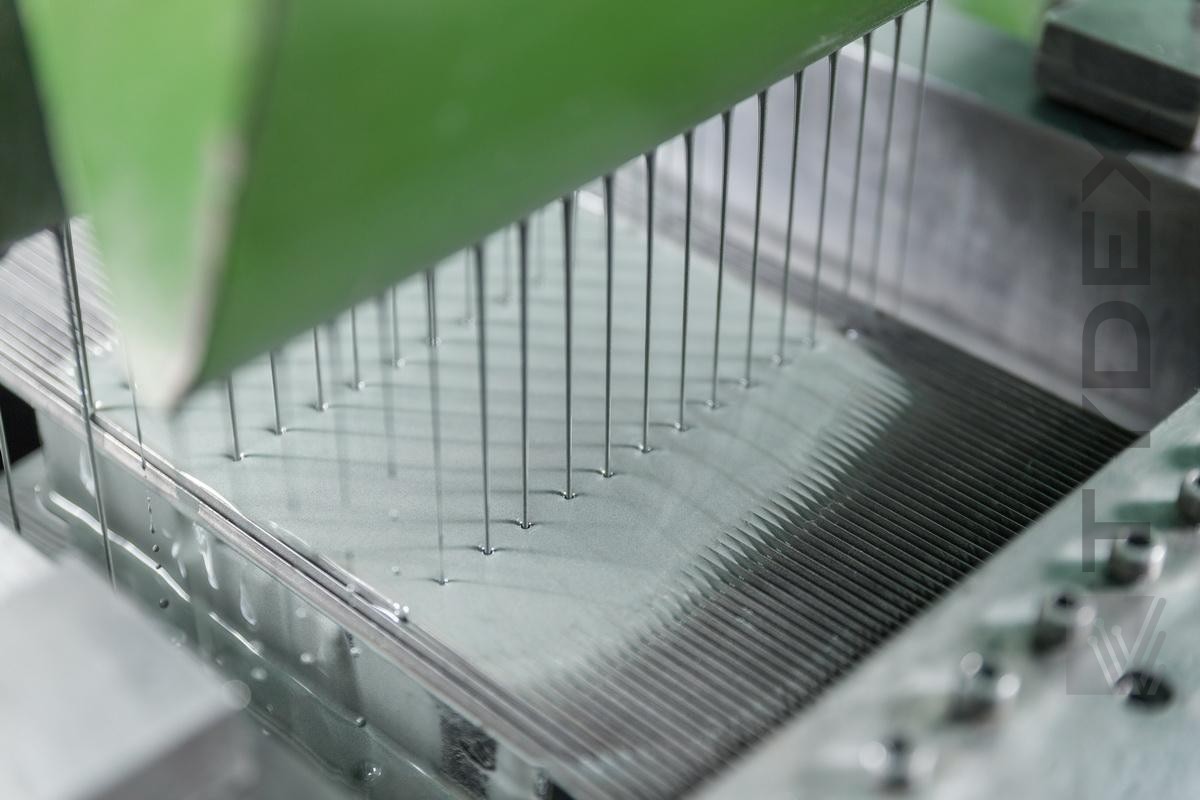

Optical blank preparation section performs cutting (fig. 3, 4) grinding (fig. 5), rounding and tumbling of optical materials, solving most preparation tasks for subsequent manufacturing of prisms, lenses, wedges, mirrors sized from 2 to 220 mm, as well as globular lenses with a minimum diameter below 1.5 mm. Crystalline materials are cut with annular-cutting machine Almaz-6M, whereas glass is cut with peripheral blade machines. The blanks are ground with surface grinders using either loose abrasive (silicon or boron carbide) or diamond tooling. Spherical grinding is performed with AShS-35 and AShS-70 grinding machines. Rounding is done with circular grinders: centerless BShS10 and centered 3A-110. Degree of rounding accuracy is up to 20 μm. Spherical blanks are produced using in-house machines.

Fig. 3

Fig. 3

Fig. 4

Fig. 5

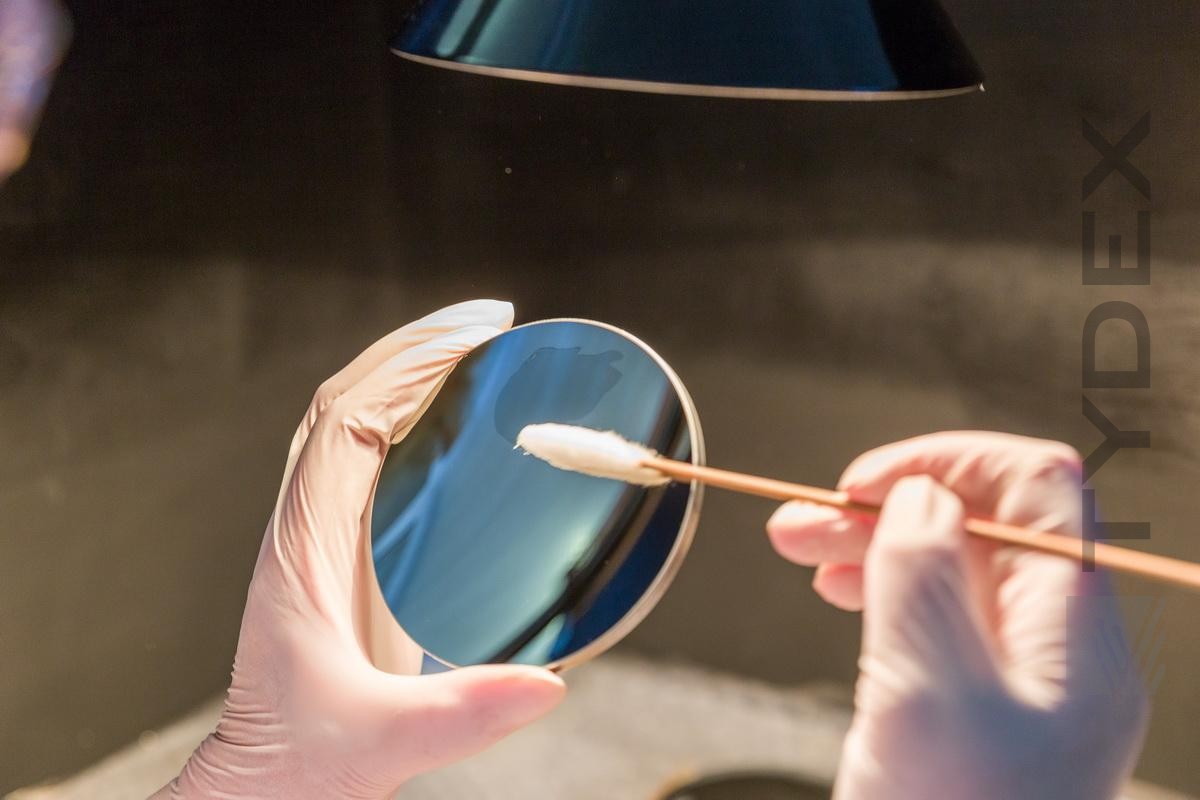

Polishing section is equipped with various polishing and finishing machines and tools capable of finishing spherical parts up to 200 mm and flat parts up to 250 mm (Fig. 6-9). Finishing of the optical components can be achieved with the following accuracy of wavelength at 633 nm : out of flat error L/10, local error L/20 for flat surfaces and L/5 for spherical surfaces, surface quality 10/5scr/dig MIL (class 2 per Russian GOST11141-84). The detailed description of our capabilities as for materials, shapes, precision and surface quality please refer to our product catalogue. Parts larger than 250 mm are manufactured in cooperation with our subcontractors. The developed processes for chemical-mechanical finishing of various crystalline materials (Ge, Si, ZnSe, ZnS, CaF2, BaF2 etc.) and mass-production of globular lenses from these materials are our key competitive advantages, both in production quality and time of manufacturing.

Fig. 6

Fig. 7

Fig. 8

Fig. 9

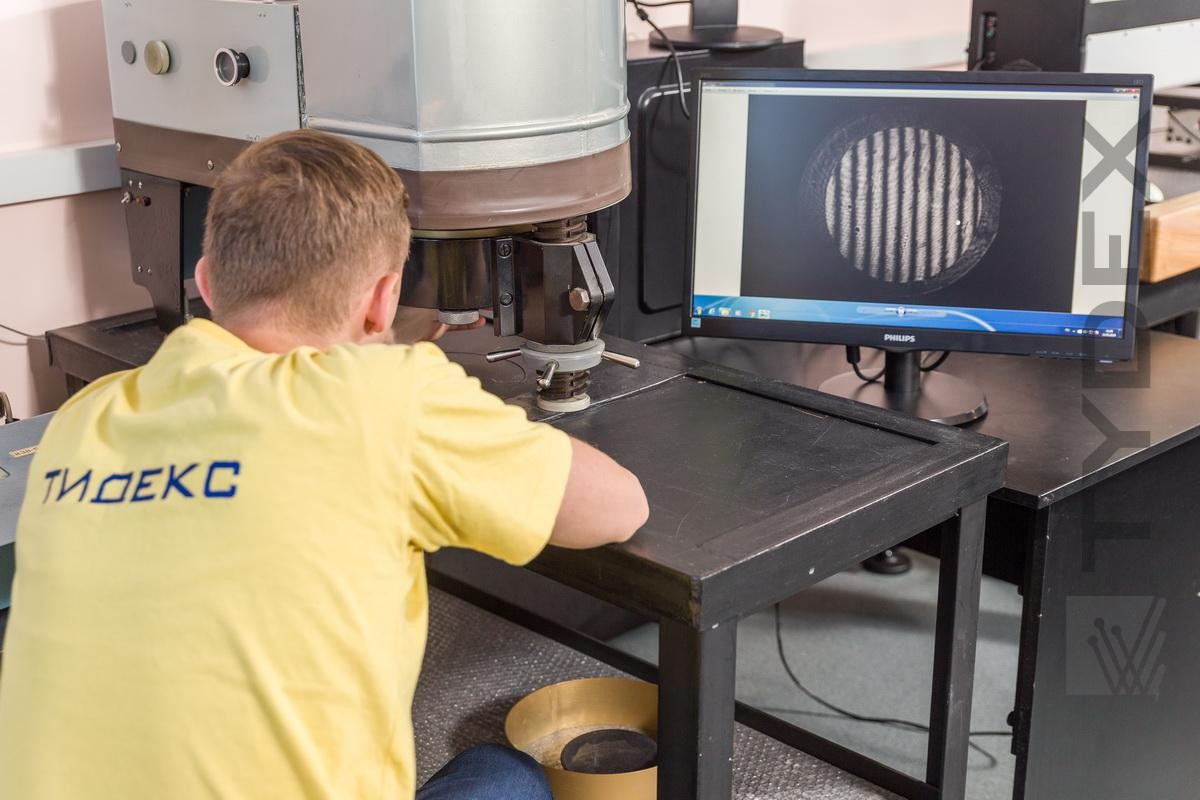

Optics quality control section is equipped with a variety of instruments required to verify conformance of all characteristics of manufactured components with appropriate precision (Fig. 10-13).

Fig. 10

Fig. 11

Fig. 12

Fig. 13

Fig. 13

For example, angular dimensions of optical parts can be verified within 3-5 arc seconds of specification (using G5M), linear dimensions to 0.2 μm (using IZV-5), surface quality to 1/10 of wavelength at 633 nm (using interferometer). Interferometry measurements of flat surfaces up to 200 mm are made with two modified IT-200 interferometers (Fig. 15-17), as well as IT-70 and our proprietary IFL-200 (fig. 13). All instruments undergo metrological certification in RosTest and have the required certificates. Spherical surfaces are checked in situ using 2500 flats. Final inspection is performed with FTI-100 interferometer (made by ZAO Difrakciya) using standard objective lenses by MPF (Germany).

Also the production facility includes the salt crystals optical parts manufacturing section . Lenses, prisms, wedges and windows can be made from KBr, NaCl and KCl with the following specifications:

- finish accuracy – 2L@633,

- surface quality class 5 per GOST 11141-84,

- outline and linear dimension tolerance ±0.1 mm,

- angular dimension tolerance 5'.

Fig. 14

Fig. 15

Fig. 16

Fig. 17

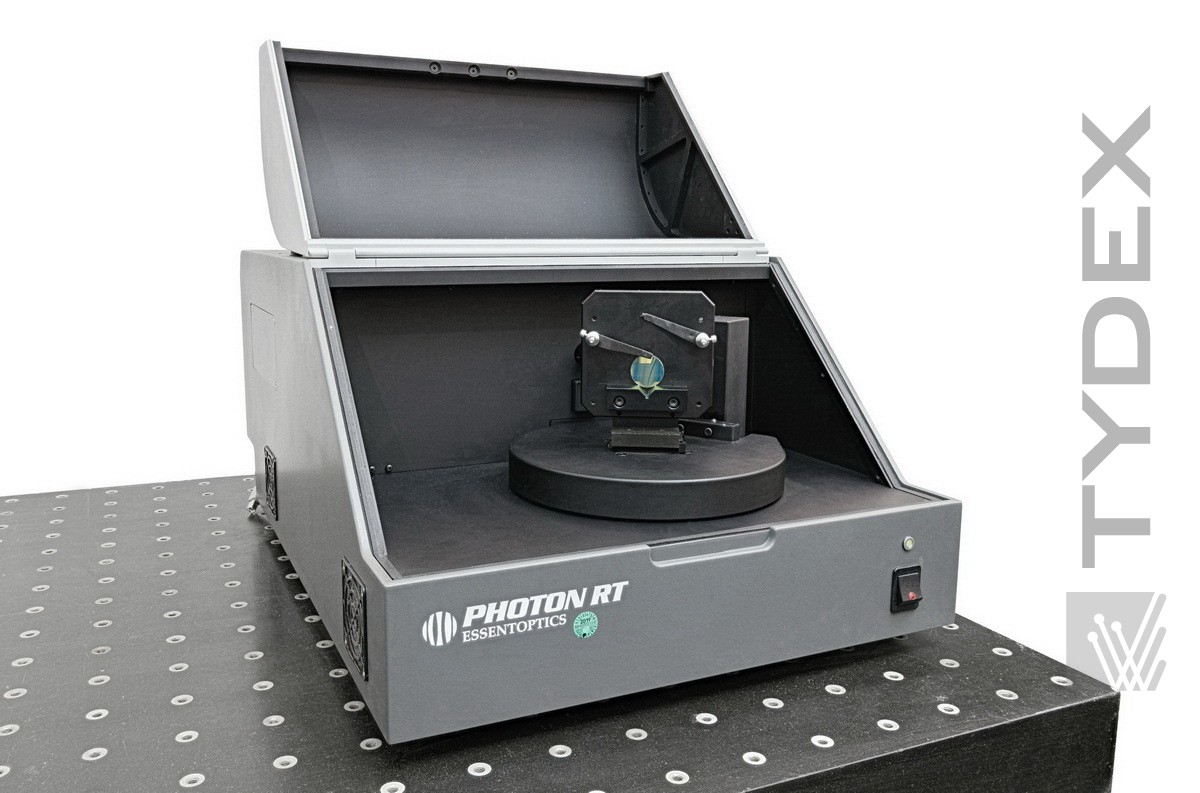

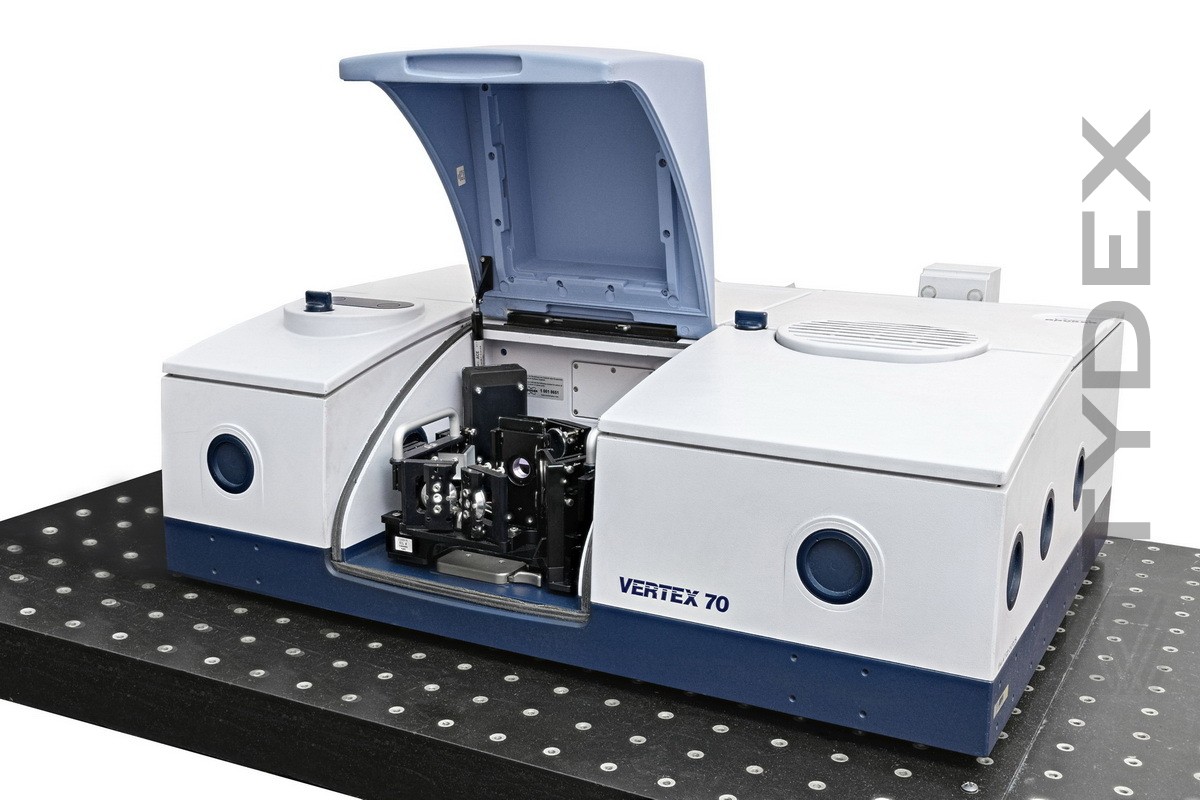

The coating department is equipped with Belorussian-made VU-1AI and VU-2MI vacuum units (Fig. 18-21), BAK-750 (Switzerland) and UVP-3 (proprietary) that can be used to apply dielectric and metallic coatings for wavelengths between 190 nm and 3000 μm. The units utilize ion-sputtering surface cleaning and ion beam assist deposition. Spectral parameters of the coatings are verified using Photon RT spectrophotometer (EssentOptics (Belarus)) in wavelength range 0.19-1.1 μm (fig. 22), and Fourier-transform spectrometer Vertex 70 (Bruker) in range 0.9-700 μm (fig. 23). Measurements are done in transmission and reflection geometry, including but not limited to polarized light. Same instruments are used for incoming spectral inspection of optical materials and uncoated ready items. The department also performs environmental testing of the coatings, testing for abrasion resistance, adhesion etc. (fig. 24).

Fig. 18

Fig. 18

Fig. 19

Fig. 19

Fig. 20

Fig. 21

Fig. 22

Fig. 23

Fig. 24

The second key area of our company includes R&D and device departments .

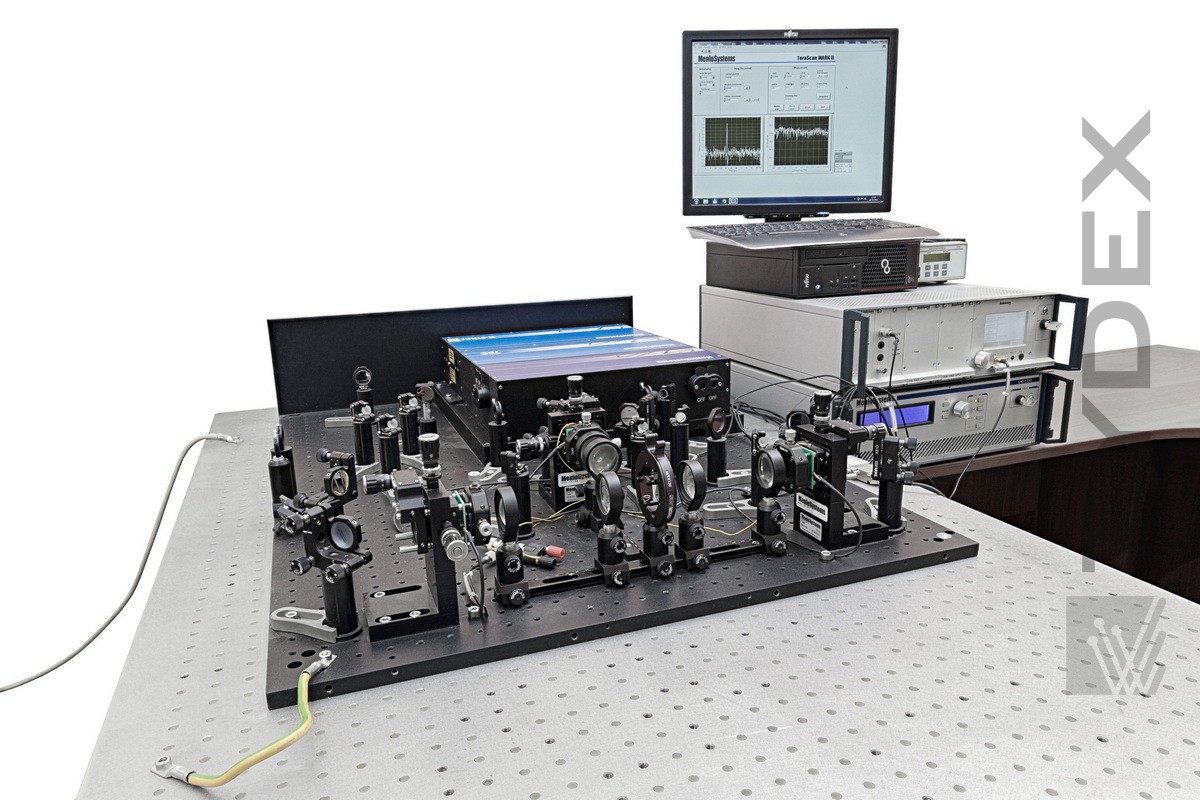

R&D department develops novel components, units and instruments for terahertz photonics applications. It is equipped with various research instrumentations, such as customized THz TDS spectrometer K-15 by Menlo Systems (Germany) (fig. 25), FTIR spectrometer Bruker Vertex 70 (Germany) (fig. 23), femtosecond IR pulse laser by Avesta (Russia) and spectrophotometer Photon RT by EssentOptics (Belarus) (fig. 22).The aforementioned instruments provide the capability of spectroscopic studies within wide wavelength range (190 nm to 3000 μm) in polarized and non-polarized light, under different angles and geometries (transmission, reflection). Developing prototypes the sector utilizes nearly almost of TYDEX production capability. For more details please refer to the R&D department.

Fig. 25

The results of the R&D department activities are handed over to the device department for small-scale production.The section manufactures optoacoustic detectors (Golay cells), electro-optical detectors of terahertz impulses, scanning THz Fabry-Perot interferometers intended for measurements of wavelength and intensity of narrow-band terahertz radiation, THz attenuators and other instruments and devices operating in terahertz wavelength range. For more detailed review of our THz products please refer to THz devices and THz optics.

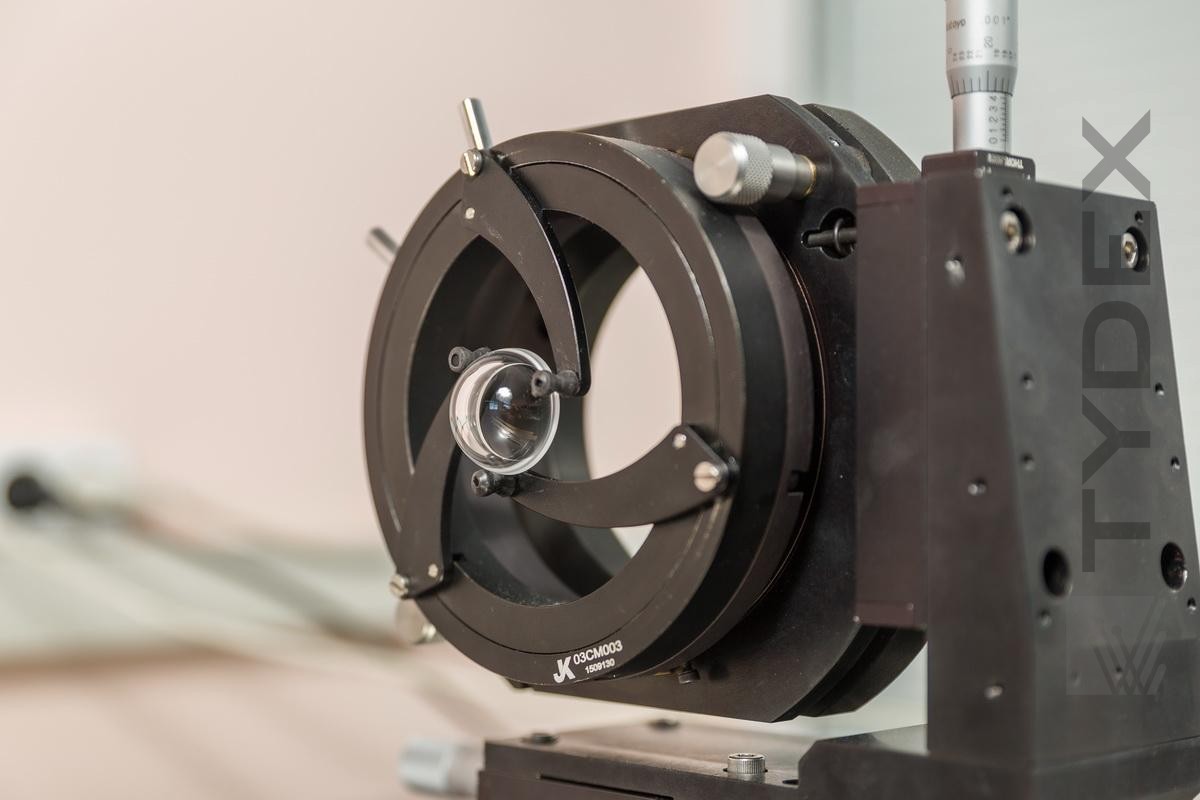

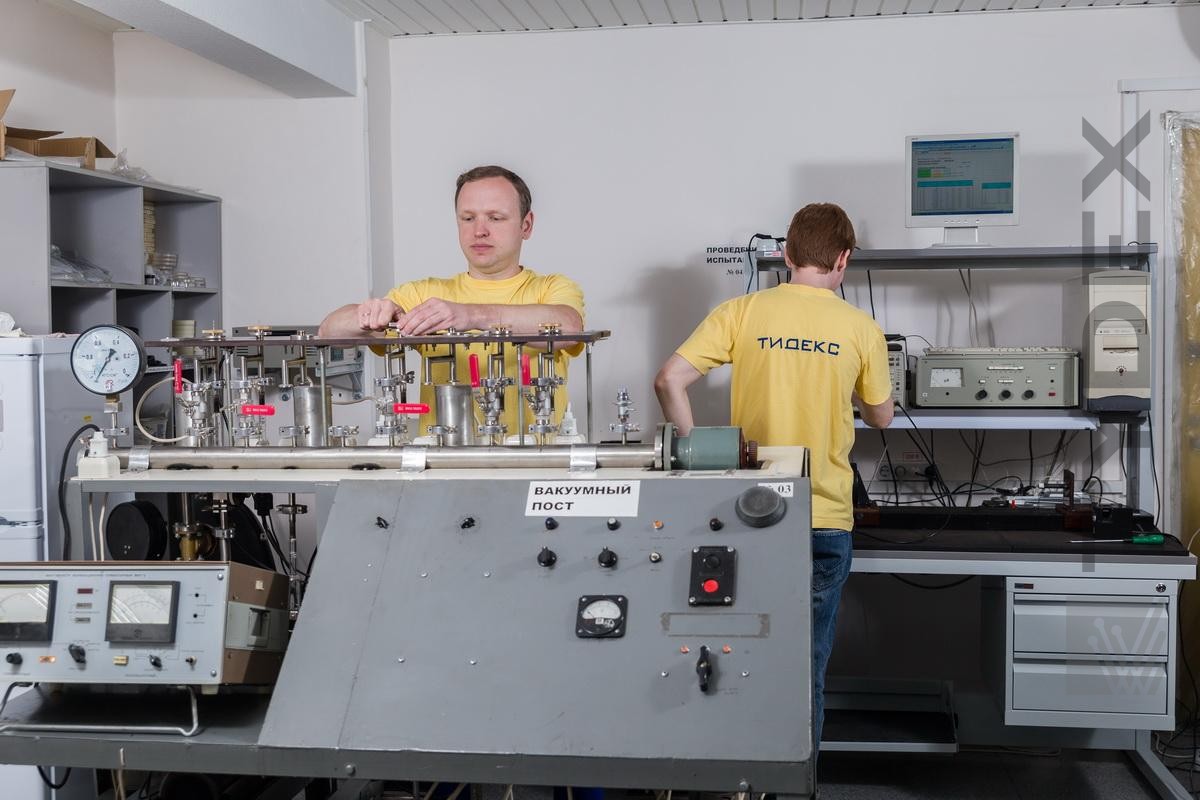

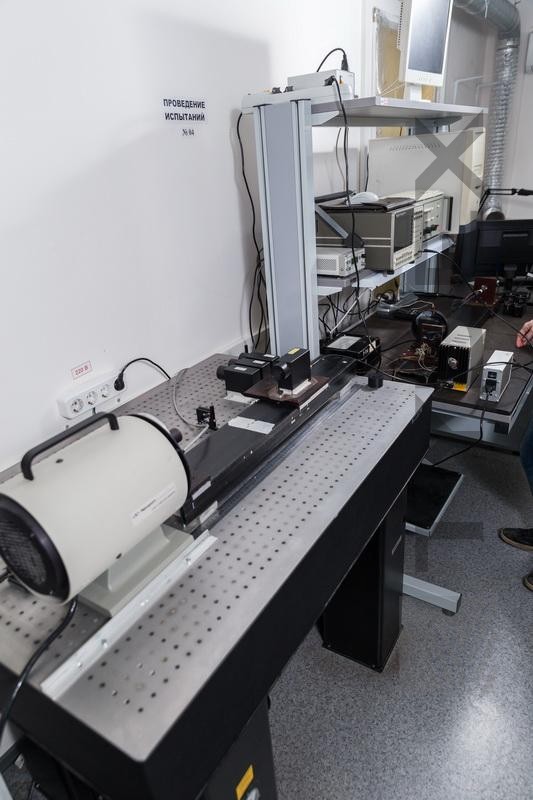

Our manufacturing processes include but not limited to organic film synthesis with subsequent vacuum deposition of coating, part assembly under vacuum (fig. 26), component tuning and adjustment (fig. 27), assembly and calibration of instruments (fig. 28) and many other activities.

The manufacturing processes utilize electronic equipment by НР/Agilent, Thorlabs, Ircon, Velleman, specialized vacuum equipment based on BOC Edwards components, vibration protection system Standa, and highly purified consumables (gazes, polymers and solvents).

Fig. 26

Fig. 26

Fig. 27

Fig. 28

Optics is ready to be shipped!

Optics Stock

Shipment/ Payment/ Warranty ...