Protective IR Windows for Unmanned Aerial Vehicles (UAV)

| Download Protective IR Windows for Unmanned Aerial Vehicles Datasheet (PDF, 652 KB) |

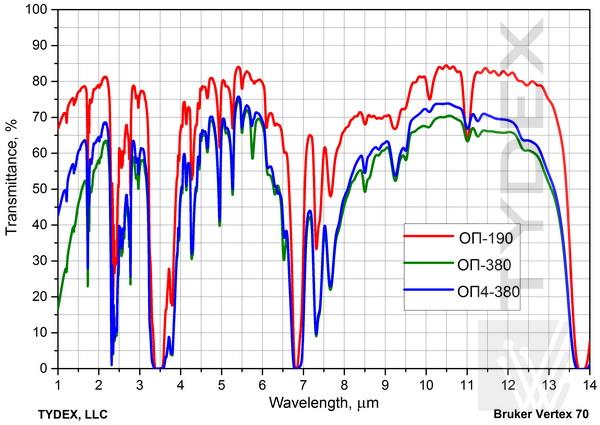

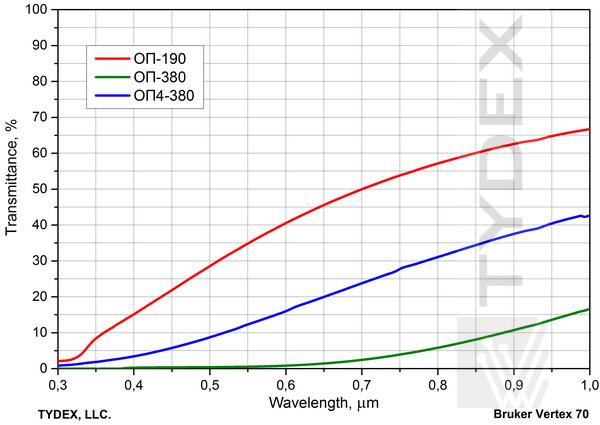

We offer a series of thin polymer films with high transmissivity in the second infrared atmospheric window, 8 to 13 μm range (see fig. 1), for the purposes where traditional crystalline IR materials, such as germanium, silicon, zinc selenide or sulfide, are economically or technically infeasible. The films are quite transparent in the first atmospheric window as well, but only in a part of the window, namely in the long wave range, 4 to 6.5 μm. Transparency of the films in the visible range is between a few percent and fifty percent, depending on film type (see fig. 2).

Fig. 1. Transmissivity spectrum of the IR films for UAV applications in 1-14 μm range.

Fig. 2. Transmissivity spectrum of the IR films for UAV applications in visible range.

The disadvantages of crystalline IR materials compared to IR films are associated with the high cost of the IR crystals themselves and the necessity of antireflective treatment to avoid high reflection losses on crystalline surfaces. The refractive indices used in the thermography of IR crystals lie in the range from 2.15 to 4.10, while for these polymers it is 1.53-1.54. Therefore, IR films do not need optical coatings, while coating increases the cost of crystalline IR windows. Lightness of polymer windows is important for lightweight aerial vehicles and is a major advantage over heavier crystals, as well as the ability to form flexible windows to any required shape.

Technical characteristics of the films are given in the table below.

| Properties | ОП-190 | ОП-380 | ОП4-380 |

| Thickness, μm | 190 | 380 | 380 |

| Refractive index in visible range | 1,53 | 1,53 | 1,53 |

| Refractive index in 8-14 μm | 1,54 | 1,54 | 1,54 |

| Refractive index above 15 μm | 1,48 | 1,48 | 1,48 |

| Tensile strength, 10^3 PSI | 14…38 | 60…180 | 60…180 |

| Flexural strength, 10^3 PSI | 8…60 | 100..260 | 100..260 |

| Shore hardness | D40-50 | D60-70 | D60-70 |

| Thermal expansion coefficient, 10^-5/ °C | 10…20 | 11...13 | 11...13 |

| Maximum operating temperature, °C | 65 | 100 | 100 |

| UV stability | stable | stable | stable |

| Degradation under sunlight | cracking | none | minor |

| Degradation under weak acids | insignificant | very insignificant | insignificant |

| Degradation under weak alkalis | insignificant | very insignificant | insignificant |

| Degradation under organic solvents | insignificant | insignificant @ Т>60°C | insignificant Т>60°C |

Maximum available film dimensions are 400x250mm.

We also produce windows from IR films of the required sizes, including framed windows per customer’s drawings.

For price quotation and delivery please fill in our request form.

Optics is ready to be shipped!

Optics Stock

Shipment/ Payment/ Warranty ...